Its Apple blossom time, much earlier than last year which was a very late season. The speed of development this year after a mild winter and 'to date' no serious frost has seen Plum, Pear, Cherry and now apple blossom come into blossom in rapid succession.

Regular readers will be aware of The English Apple Man's annual involvement in The Brian Moore Golf Day at Cherry Lodge Golf Club in early September, a very worthy event raising valuable funds for The Threshers Day Nursery at St.Mary Cray in South London.

Having offered an 'Auction Prize' of a day on a 'ultra modern' apple farm, purchased with a generous offer by Rob MacKenzie, this week I was able to fulfill that 'promise' with a visit to A.C.Goatham's new storage and packing complex at Flanders Farm on the Isle of Grain and one of Goatham's state of the art farms, Gore Farm.

The English Apple Man spent a most enjoyable Thursday with Rob MacKenzie and his wife Tracy and sons Cameron and Jake hosted by Darren Wallis one of A.C.Goatham's technical team on a visit to the company's Flanders Farm headquarters for a tour of the packhouse, and then onto Gore Farm at Upchurch for lunch at The Barnyard Restaurant followed by a walk through the apple orchards where the Gala, Braeburn and Rubens were all in full bloom.

There is lots to see at Gore Farm; bees working in the orchards and an eclectic mix of animals to entertain visitors, including this very special Donkey!

The day was an altogether enjoyable experience, not least because Rob, Tracy and their boys were a joy to entertain, expressing a genuine interest in all aspects of the fruit production and packing process.

N.P Seymour - a 40 year success story!

On Wednesday of last week; e.g. 9th April The English Apple Man joined growers and an eclectic mix of members from the fruit industry at the 40th anniversary celebrations of N.P.Seymour at their headquarters in Flishinghurst near Cranbrook in West Kent.

On Wednesday of last week; e.g. 9th April The English Apple Man joined growers and an eclectic mix of members from the fruit industry at the 40th anniversary celebrations of N.P.Seymour at their headquarters in Flishinghurst near Cranbrook in West Kent.

Nick Seymour first came to my attention more than 30 years ago when I discovered his engineering skills. Always a man you felt comfortable with; an engineer of the highest capability, not a natural salesman, but one who built a solid business on knowledge and integrity.

Nick Seymour learnt his skills with Drake & Fletcher in Maidstone and Ashford, training as an agricultural engineer. Following his time at Drake & Fletcher, Nick spent a year running a small workshop for H A Carpenter & Sons at Wanshurst Green. A year later (1974) at the age of 22 Nick ventured out on his own, with a mobile workshop; a 'van and tools' and a great deal of enthusiasm.

In 1977 Nick moved to Avon Works in Goudhurst and a permanent workshop. New regulations in 1978 required all tractors to be fitted with a safety frame. Nick embraced the opportunity 'gearing up' and fitting the frames 'on farm' and the fact that most were on fruit farms gave him an 'entre' into the world of fruit growing.

In 1984 Nick took on a dealership for FENDT tractors and this year celebrates 30 years as a FENDT dealer.

In 1984 Nick took on a dealership for FENDT tractors and this year celebrates 30 years as a FENDT dealer.

The English Apple Man comments:

Having lost my father in 1975 and subjected to a torrid few years battling the elements; drought (1976) frost (1977) hail (1978) small fruit and the full impact of the EEC (1979) I needed the solid support of people with integrity and 'I was lucky' with Nick and other key people in the industry helping me through my 'annus horribilis' x 5 (1975-1979. The subsequent 'annus mirabilis' (1980 -1985) when everything seemed to go right allowed me to take the business forward and new investment became the norm!

It was in the second phase that I bought a FENDT Tractor from Nick Seymour; a demonstrator, so a bit cheaper than list price, I seem to remember paying circa £12,000 for it. Nick had demonstrated the tractor in February, but I had decided it was to expensive for my budget; come the spraying season in late March the weather was awful (its not just 2014 that started very wet) and on a bank field planted with Bramley, the '2 wheel drive' Ford went down, but not up again due to the very wet ground; we put a David Brown and chain infront and attempted to pull the sprayer up with both tractors, but 'no go' and out of desperation 'emptied the tank' onto the field' (not good practice) but still we struggled.

Desperate, I rang Nick; "do you still have the Fendt, I enquired (fingers crossed) YES, came the reply. Would you come out and try it on this slope?

Desperate, I rang Nick; "do you still have the Fendt, I enquired (fingers crossed) YES, came the reply. Would you come out and try it on this slope?

Nick arrived, and after recovering the sprayer and two tractors we filled the sprayer (with water) and Nick went 'up and down' the bank with consummate ease. Needless to say I bought it there and then!

The one I am 'posing in' last week, is I understand - £48,000 and the 'all dancing. bells & whistles model is circa £75,000

By the end of the 1980's the business justified more workshop space and in 1992 N.P.Seymour moved into their current AVON WORKS in the hamlet of Flishinghurst on the edge of Cranbrook.

Much of the success of N.P.Seymour is due to the flexibility to take standard equipment, designed to 'fit all' situations and modify them to an individual growers need. This has led to Nick Seymour and his team building 'tailor made'equipment to a design agreed between Nick and an individual grower.

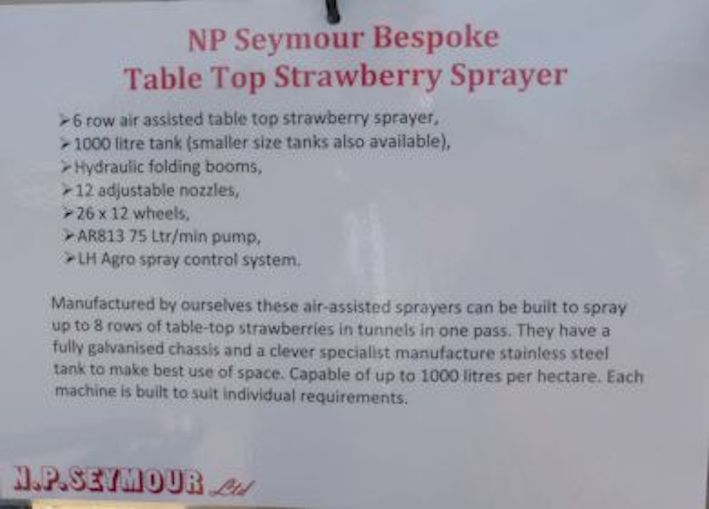

One of the specialist pieces of equipment on display at the Open Day was a sprayer designed for table top strawberries.

Over the years Nick Seymour has been at the 'cutting edge' of new developments. One major step forward was when he took the research work carried out at East Malling Research into optimum nozzle sizes for orchards sprayers. The research indicated a size of 120 Micron but found that size was not easily available. Typical of Nick's inquisitive mind he searched and found industrial nozzles suitable for the purpose. Modifying orchard sprayers allowed a reduction from 100 gallons per acre to 40 gallons an acre and with it a much improved application efficacy.

The English Apple Man was one of those early growers who moved to the more efficient and environmentally friendly nozzles.

I remember we were able with Nick's help to reduce the volume per acre down to 20 gallons per acre (gpa) on our mature trees and as low as 10 gpa on trees by reducing the number of nozzles for trees with less height and density. The crop protectant was mixed in line with the makers label in 20 gallons of water but by reducing the volume on trees with less density, a reduction of up to 50% could be achieved without loss of efficacy.

BELOW: the Table Top Strawberry Sprayer designed and built by Nick Seymour.

Table Top Strawberry Production as a system is a major contributor of UK Strawberries.

Many of the suppliers who attended included; from Agri Finance, Agrofrost, Aweta, Berthoud, Bucher Vaslin, Burg, Fendt, Micron, Perfect, Pessl and Reco.

The English Apple Man took particular interest in Agrofrost manufacturers of frost protection products.

For frost protection in high value crops the Agrofrost Frostbuster or Frostguard puts growers minds at rest. The machines work by burning propane gas to provide a heated air supply, which is then blown across the orchard, vineyard or into the polytunnel.

On the left the Frostbuster and on the right the Frostguard

.jpg)

The area of use that caught my imagination was 'cherries' grown under plastic tunnels; the ability to warm the air around the trees is a plus point for pollination as well as reducing frost risk.

Patrik Stynen - representing Agrofrost at the Open Day told me they are used extensively on cherries in Belgium & Holland. Placed strategically at the end of a cherry tunnel, one Frostguard can protect one hectare of cherries.

Behind every successful Man there is a good Woman (so the saying goes) and behind Nick is Barbara who has supported him for all those 40 years. Now their daughter Claire is taking on more and more responsibility, currently in charge of the impressive Sales & Marketing operation. N.P.Seymour will surely celebrate many more anniversaries in the capable hands of a Seymour!

That is all for now............next week a lesson from two of our industry's 'YOUNG GUNS'..............

Take care

The English Apple Man