The English Apple Man reviews presentations from the recent EMR Tree Fruit Day.......

This week's Journal looks at 'Post harvest treatmen' of cherries - and the latest research into fruit wall production systems.

Cherries are not a 'five minute wonder' - modern post harvest storage is extending the season, enabling UK consumers the enjoyment of sweet juicy English grown cherries....

Post harvest treatment of cherries - The latest research into fruit wall production systems.

Below: The EMR Tree Fruit Day was very well attended

Oliver Doubleday - Post-harvest treatment of cherries; a brief review........

Oliver Doubleday's presentation highlighted the influence technology has had on post harvest storage.

Oliver Doubleday's presentation highlighted the influence technology has had on post harvest storage.

Oliver reminded the audience of the factors defining taste - Salt - Sweet - Sour - Bitter & Umami (glutamate)

Our predilection for umami - the only recently recognised (by western scientists) "fifth taste", after salt, sweet, sour and bitter - is a fascinating piece in the jigsaw of our gastronomic evolution. Since studies confirmed just a few years ago that our mouths contain taste receptors for this moreish savoury taste (the other four "basic tastes" had been widely accepted for, ooh, a few thousand years....

Below: Criteria for judging when to pick

Size (also weight) - Brix (% sugar) - Colour - Firmness - Acidity (% malic acid, titrated to pH 8.2)

Measuring Strig retention (severance force) is a useful independent measure of ripeness. It is also important

Measuring Strig retention (severance force) is a useful independent measure of ripeness. It is also important

not to lose pedicle during storage; varietal differences vary from weak to strong; e.g. Kordia weak, Penny strong)

increasingly, producers are assessing the time of harvest when the pull force required to remove the fruit from the pedicle reaches a certain force

The balance of sugar & acid is critical. Cherries have relatively low levels of flavour compounds - "smell cherry vs strawberry" - Taste is king!

Below: Factors affecting storage

Variety - some varieties store better than others - Timing of pick - Age of cropping wood - Crop load an excessive load retards harvest & softens fruit, reducing quality)

Rootstocks have influence - although the principal effects of rootstock are on flowering time and precocity. Soil moisture deficit - Nutrition, including fertigation and foliar feeds - Gibberellic Acid - Relative humidity - Sunlight; all play their part...............

Sugar and Acid are important; Sugar may vary between 14 - 25% - Oliver said many varieties are 'unripe' below 16% sugar.

Acid variation is an indicator - from 0.50% (late stored or over ripe fruit) to 1.20% (unripe) - Sugar concentration is 15 - 55 x greater than malic acid - 20 x for excellent, fresh, ripe fruit; 40 x for late stored fruit - As acidity is preferentially lost through the Krebs Cycle the proportion of these elements, the two major components of taste in cherries, changes...............

The Krebs cycle (or citric acid cycle) is a part of cellular respiration. Named after Hans Krebs, it is a series of chemical reactions used by all aerobic organisms to generate energy. Its importance to many biochemical pathways suggests that it was one of the earliest parts of cellular metabolism to evolve.

Temperature influences firmness & bruising - Warm fruit is softer (hence avoiding harvest during very hot conditions by starting earlier!) - Chilled fruit is more susceptible to bruising and pitting - Avoid handling fruit below 10C.

Respiration

It is critical to cool fruit; if not it gets hotter; cooling avoids depleting substrate - literally burning quality!

We can slow respiration by reducing oxygen and accumulating carbon dioxide, but must avoid very low oxygen conditions that will give rise to anaerobic respiration and taste taints. Oliver said a 'genetic variation' in peoples ability to detect taints influences an individuals perception.

Systems of rapid cooling used in Cherry 'post harvest' operations

Air Blast Chilling

3/4 - 7/8 cooling to target temperature in 2 hours in well perforated and ventilated crates, 5 kg fruit in 60 x 40 x 15 cm units. Effects of sub-optimal air flow, including shielding should be noted, and implications considered of packaging on airflow.

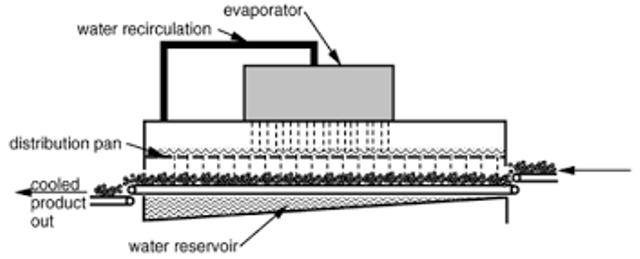

Hydro cooling

Hydro cooling is 24 x faster than air, but must have adequate water flow for stacks of trays - water can crack fruit so important to minimise duration of hydro cooling - water must be clean (chlorine or chlorine dioxide treatment) - Avoiding impact damage is a MUST: fruit drops <10cms, water droplets <15 cms (put mesh over top of

trays)

Below: Static Hydrocooler - and - A Portable Hydrocooler

Good Storage principles: A

Manage temperature -avoid hot conditions - What is the temperature target? - Avoid <10c if handling, otherwise 0c is target - important to maintain humidity; water loss = wrinkled skin, shrivelled pedicle and weight loss.

Modified Atmosphere Packaging crates (Janny) - shrouds (SDA Packaging Ltd, Amcor), bags (Amcor) have

high humidity, low O2 and high CO2 which can reduce fungal infections.

Good Storage principles: B

Optimum regime - O2 @ 3 - 10%, CO2 10 -15% (UC Davis Postharvest Technology Centre).

Must measure gases and avoid very low O2 (causes taints from fermentation) High CO2 discolours and also taints.

Consider effects of sealing warm fruit (> 10C) and difficult to subsequently cool. Disruptions to refrigeration all more acute with 'stringent' bags (lowest possible O2 highest CO2). Majority of global experience is of fruit stored during sea freight. In China cool chain disruption at the end of a journey is very common

When removing fruit from store - Equilibrate fruits' O2 & CO2 in air prior to warming after Modified Atmosphere (MA) storage.

Review

When to pick? - monitor characteristics under your husbandry conditions - remember the importance of rapid chilling and the virtues of Air & Water chilling. Don't forget the relationship between temperature, firmness & bruising. Don't handle fruit below 10C - consider effect of shielding & packaging and flow rates for cooling - maintain the correct atmosphere; low O2 high CO2 avoid fermentation taints - remember the role of acidity in taste and preferential loss of acidity during ripening & storage (especially over ripe fruit).

For a comprehensive look at Cherry Hydrocooling and Packing, visit STEMILT in Washingon State USA one of the biggest Cherry operations in the World; The English Apple Man visited Stemilt in November 2001 - the hydrocoller was under wraps then as it was apple harvest time.

Also a YouTube clip of a Hydrocooler in action

.................................................................................................................................................................

The second presentation featured in this week's Journal is Abi Dalton' review of the AHDB Fruit Tree Wall project.

The second presentation featured in this week's Journal is Abi Dalton' review of the AHDB Fruit Tree Wall project.

Abi Dalton - Trials Co-ordinator @ FAST

LATEST RESEARCH - FRUIT WALL PRODUCTION SYSTEMS

AHDB - TF207 FRUIT WALL TIMING

The development board, formerly known as HDC (Horticulture Development Company) has be affiliated with the agricultural sector to become AHDB the Agriculture and Horticulture Development Board

Abi outlined the background to this AHDB funded project; the fruit wall concept adapted trees at Adrian Scripps Parsonage Farm at Cobham in Kent. Fruit Walls originated in France in the 1980's - 2015 was the penultimate year of trial and Abi reviewed how the trees are adapting.

Below: Library picture of AHDB - Gala Fruit Walls at Parsonage Farm

Materials & Methods

The 5 year trial was established in 2012 with Gala as the chosen variety; planted at distances of 3.5 metres x 0.5 metre in the row, there are 5 treatments & 5 sub treatments, with 4 replicate rows of 20 trees per plot.

How are fruit wall cut timings determined?

Assessments are made of Leaf counts - measuring Shoot length and leaf numbers, Yield, Fruit maturity at harvest - Fruit quality, Leaf Mineral Analysis and Fruit Dry Matter.

Conclusions reached demonstrate later cuts had better growth control; there were no significant effects on 2015 yield, fruit size, weight, maturity, Brix (sugars), firmness or dry Matter.

Fruit colour improved on 9 & 6 leaf cuts; winter hand pruning produced the highest cumulative total yield - percentage of Class 1 fruit highest for inter pruned Pink Bud. Inter tree pruning; lower total yields but increased C1 - Cropping wood in mechanically pruned plots is increasing.

The trial process for 'tree wall mechanical pruning' requires finding the optimum stage for making the cuts; the stages are determined by the number of leaves on the new (young) vegetative growth; e.g. when 6 leaves are formed or 9 leaves are formed

Grower Action Points

Abi stressed the importance of assessing the orchard before any pruning takes place; where tree control is the major consideration, delayed pruning is advised. The optimum fruit wall timing is yet to be determined.

Financial Benefits

There is a potential for reducing pruning costs and skilled pruning labour requirements. The cumulative yield was reduced for later cut fruit wall conversion. This is when conversion from a standard hedgerow system is converted - either by a winter cut (preferred) or by conversion by summer cuts

Abi thanked - AHDB - Adrian Scripps Farms - Parsonage Farm Staff and FAST LLP Trials Team, Advisors & Laboratory personnel for their contribution to the TF207 FRUIT WALL TIMING project.

LATEST RESEARCH - FRUIT WALL PRODUCTION SYSTEMS

Next Abi Dalton reviewed the TF206 FRUIT WALL TYPE project.

Introduction and Background - Fruit wall concept - adapt trees - Project outline, 2015 is the second fruiting year and Abi reviewed how the trees are adapting?

Materials & Methods

This is a 5 year trial commencing in 2014, using Gala - Planting distances 3.5m x 0.8m - 5 tree type treatments and 6 replicate rows of 10 trees per plot.

The five tree types:1 Year 5 + Branches: 1 Year unfeathered: 2 Year Old: Standard Knip: Twin Stem:

The objective here, is to assess how each tree type performs as a fruit wall when grown from a young tree, rather than the 'conversion' of established trees used in TF207 FRUIT WALL TIMING

How are fruit wall cut timings determined?

By assessments of leaf counts, yield and class, fruit physiology and quality and tree physiology

Conclusions

Significant effect on yields, fruit weight and tree volume; it is not yet clear whether responses are due to establishment of the different tree types or pruning. It is not yet conclusive which tree type most suited to fruit wall system!

Grower Action Points

The 'Fruit Wall' cut was carried out when 9 new leaves had emerged on current season's growth. It is important to make regular leaf counts to establish growth stage before pruning. Abi said other actions points will be determined in the remaining 3 years of the trial.

Financial Benefits

Abi Dalton summarised; "There is potential for reducing pruning costs and skilled pruning labour requirements, but it is too early to cost the future savings".

The English Apple Man Comments: "the future system will be a taller, narrower hedge row format than the systems common at the turn of the century; whether mechanical pruning becomes the standard is yet to become clear - the increase in labour unit costs is going to be a huge challenge; the availability of labour may well become an equal challenge to our future. The key to it all is not just the cost of pruning, but profit per acre/hectare which is determined by yield, quality, and particularly, consumer attraction - e.g. price of the fruit back to the grower

..................................................................................................................................................................

Produced in Kent awards

The winners of Produced in Kent's Taste of Kent Awards have been revealed today (4 March), after being recognised as Kent's ultimate food and drink champions at this year's black tie event, which was held at the Kent Event Centre, Kent Showground, Detling.

And finally.......last Saturday we enjoyed a Birthday Lunch at Texture in Portman Street London to celebrate my brother's 70th Birthday on 1st March - St.David's Day......

![]() Visit the website by clicking on; TEXTURE

Visit the website by clicking on; TEXTURE

The pictures were taken by David Usill a friend of my brother and a distinguished photographer and balloonist. Click on windowontheworld to visit David's website.

That is all for this week........

Take care

The English Apple Man