We live in an age of technology, the exponential rate of expansion is sometimes difficult to keep up with.

Drones are suggested as the panacea for many tasks. But when did the first (UAV) Unmanned Arial Vehicle first appear?

Drones are suggested as the panacea for many tasks. But when did the first (UAV) Unmanned Arial Vehicle first appear?

The first stop in our drone history timeline is the very early history of drones. First, for those who don't know, it's important to establish that the word "drone" simply refers to any aerial vehicle that is unmanned.

That is, the pilot does not sit or stand within the vehicle itself.

By this definition, the earliest unmanned aerial vehicle in the history of drones was seen in 1839, when Austrian soldiers attacked the city of Venice with unmanned balloons filled with explosives.

UAV technology improved throughout World War II (which saw a number of technological advancements as we all know) and into the Cold War as well.

What we do know is that modern drone warfare began in earnest in 1982, when Israel coordinated the use of battlefield UAVs alongside manned aircraft to wipe out the Syrian fleet with very minimal losses.

2006 was the first year that the (US) Federal Aviation Administration (FAA) issued a commercial drone permit. They issued an average of two of these permits a year for the next eight years - that was all that was requested.

As unmanned aerial vehicle technology improved in the military sector, those same technological improvements could be used in the private sector.

According to a Wall Street Journal report, the history of non-military drone use began in earnest in 2006.

Then, in 2013, Amazon CEO Jeff Bezos announced that the company was considering using drones as a delivery method, igniting the public's interest in drone history. In 2015, the FAA issued 1000 drone permits, a number which more than tripled to 3100 permits in 2016 and which has continued to grow in the time since.

In the world of farming and horticulture Drone Technology is being utilised at an exponential rate!

In this week's EAM Journal we will highlight OUTFIELD TECHNOLOGY a young company growing fast in field of crop forecasting.

Over the last couple of years, The English Apple Man has got to know the founders of Outfield:

OLI HILBOURNE - FOUNDER & OPERATIONS DIRECTOR and JIM MCDOUGALL - FOUNDER & COMMERCIAL DIRECTOR.

Working with a team of very bright young graduates, they have rapidly set about revolutionising crop prediction and technical tasks using Drones.

Oli Hilbourne delivers an overview - This is where we see fruit farming going in the future.

On the farm

In the Future - The Farm manager is notified on his phone that his sprayers are ready to deploy to the orchards. There's a prescription recommended, with notes from his agronomist. He makes a decision and presses go.

In the Future - The Farm manager is notified on his phone that his sprayers are ready to deploy to the orchards. There's a prescription recommended, with notes from his agronomist. He makes a decision and presses go.

- Automated spray systems are activated in the farm court yard and drive themselves to the right orchards.

Once there they carry out precision dosing from various chemical tanks in the sprayer at the correct rate for each tree to maximise production

- The growers will always know their farm better than the computer, so the grower can use the app to check and correct the prescriptions. He checks the map and reviews images for each location, then marks areas for his team to go and check manually and confirm before the sprayer is deployed

- The growers will always know their farm better than the computer, so the grower can use the app to check and correct the prescriptions. He checks the map and reviews images for each location, then marks areas for his team to go and check manually and confirm before the sprayer is deployed

- The data the farmer reviews was all gathered that morning by autonomous drone flights, self-launched from a boxes situated on the farm which cover the entire orchard every 3 days giving in depth data from blossom through to harvest

- All of this data is also informing yield predictions, used by the grower to plan labour, storage and logistics. This is shared with the marketing desks to arrange forward contracts and prime the supply chain for international trade.

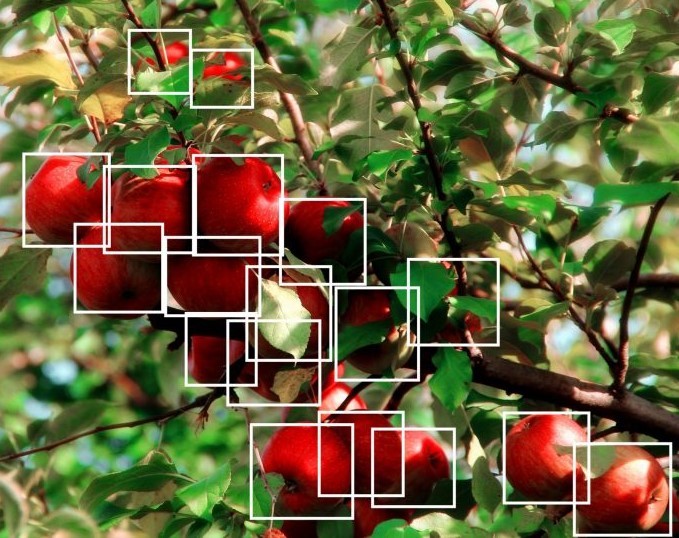

Below: Arial profiling Blossom intensity

- Over the course of several seasons, this data can be used by the grower to track trends in the orchards and in the market.

- Over the course of several seasons, this data can be used by the grower to track trends in the orchards and in the market.

This allows them to negotiate better insurance premiums, make long term decisions about planting and varieties, and continuously improve the farming practices for maximum value.

With the growers permission, anonymised and aggregated datasets can be used to benchmark growers and increase efficiency, or to track the impacts of the changing climate and get in front of future challenges.

The current state of the art

This is where we are right now in making that future a reality:

- Outfield growers are already launching off-the-shelf DJI drones, which survey orchards automatically to flight plans provided by the Outfield's system. In the coming years these same drones will work with 3rd party HEROTCEH8 self launchingself-launching "drone-in-a-box" solutions, and we're undertaking early trials with a system this year.

- Outfield growers are already launching off-the-shelf DJI drones, which survey orchards automatically to flight plans provided by the Outfield's system. In the coming years these same drones will work with 3rd party HEROTCEH8 self launchingself-launching "drone-in-a-box" solutions, and we're undertaking early trials with a system this year.

- The imagery analysis is now carried out online using Outfield algorithms to provide per tree blossom cluster counts and fruit counts, with heat maps of the loadings in the orchards. Our target accuracy for blossom cluster counts and fruit counts this season is within 10%, and last season's data is looking really promising.

This data is also being overlaid with soil maps in Hutchinson's Omnia platform this season.

For the coming years we have projects with universities UEA and WUT on fruit colouring and sizing, and we're working on tree data (growth and canopy density) this season too. There are also data layers we're interested in from satellite imagery providers working on plant health analysis - this is some way off but diagnosing trees from imagery data might be possible in the future.

- We can provide results from surveys back to growers online in less than 24hrs already, with plans to speed that up this year. It's really easy to share Outfield with other farm staff and agronomists, informing decision making and management. There are a whole host of different management platforms out there, and Outfield is set up to interface with them all.

- Automated spraying is already a reality, with systems like GUSS Variable rate precision spraying is something we're trialling this year as part of the

IUK funded PODS project Growers are also trialling using Outfields maps with existing sprayer systems to make data driven zonal applications with sprayers. More homogenous orchards lead to higher yields and lower fruit waste in orchards.

Note "There is substantive tree-to-tree variability in tree structure (size, density) and crop load and quality in tree fruit orchards which are the major causes of less than optimal, often poor, overall yield and quality. Previous work in Innovate UK project 101405 showed that tree-to-tree variability in yield ranged from 2-3 fold in the six most productive and uniform apple orchards in the UK, with much greater variability in poorer orchards. Larger scale within-orchard variability and inter-annual bienniality also contribute to poor performance.

- Growers and POs in the UK and France are using Outfields yield forecasts to get a more accurate estimate of yields and maximise sales value for fruit.

- Growers and POs in the UK and France are using Outfields yield forecasts to get a more accurate estimate of yields and maximise sales value for fruit.

Why this is so important

There's a wave of new technologies across the agricultural sector. Looking at the arable sector, there are data platforms and market places such as KISSANHUB and YAGRO infield robotics companies (like small robot company), scouting and surveying services (sensefly and drone ag), drone sprayers (DJI mg-1s), satellite data (agrimetrics) and so on and so on.

A lot of this technology is only just emerging in horticulture because high value, perennial, 3D crops are more challenging to digitise. The solutions are far more important and valuable though, and to enable all of these technologies in horticulture we need up to date, accurate insights made quickly, cheaply and easily.

As the sector is forecast globally to grow by 40% over the next 2 decades whilst resources like land and water are becoming ever scarcer, we need to evolve so we can thrive.

Jim McDougal - Commercial Director - Summarizes

Being precise about how we manage food production is a huge part of making productive, sustainable horticulture a reality, and it all starts with high value data and clever analysis. The data alone is not a complete solution though, and that's why we know that Outfield is only one piece of the puzzle.

We're very good at mapping fruit and blossom in orchards, and there's a lot more to come there, but we don't build drones, provide agronomy services, sell fruit, build sprayers, map soils, harvest orchards or any of the hundreds of other technologies that can be deployed to support a modern fruit farm. That's why we aren't shy about partnering with the best in class from all of these other areas to make real changes in the sector.

For an excellent and informative video presentation, Click on Outfield Video

The English Apple Man Comments:

As a former grower, with practical experience of more than 60 years, the use of technology has always been a fascination.

However, in the days of my youth, today's technology was not even a dream. Pruning tools were a saw and secateurs (now battery powered electric secateurs) harvesting was all be hand with long ladders (now with picking trains and picking rigs) grading depended on manual inspection on a basic grader (now grading is controlled by computer for sizing and quality inspection & much of the packing is automated) - crop estimation in those days depended on counting fruitlets on representative trees, taking measurements and projecting the numbers. size and quality at harvest; simple mathematics. Experienced growers could/would, with crop history of their orchards behind them, deliver pretty accurate forecasts.

The element that caught most out was the overall fruit size at harvest - a 5mm difference in fruit size could result (and often did) in 20% more or less than the estimated crop.

Using the Outfield software growers will be able to target variations in flower intensity allowing more strategic thinning of densely blossomed areas and more accurate estimation of fruit size x numbers x colour/quality = yield at harvest.

![]() That is all for this week

That is all for this week

Take care

The English Apple Man